Choosing the right industrial cable solutions is crucial for safety, efficiency, and long-term performance. Whether you are powering machines, sending data, or supporting automation, the right cables help your systems run well. They also prevent failures and costly repairs.

But with so many options, how do you know which cable is best for your project? This guide will break it down into simple, easy-to-understand steps to help you make the best choice.

Understanding Your Project Needs

Before you choose a cable, ask yourself:

In what environment will the cable be used? (Manufacturing, power distribution, automation, etc.)

What conditions will it face? (Heat, moisture, chemicals, outdoor exposure)

What’s the voltage requirement? (Low, medium, or high voltage)

Are there any industry standards it needs to meet? (UL, NEC, IEEE, or ISO)

Once you know these key factors, you can narrow your choices. This will help you find the right industrial cable solutions for your needs.

Understanding Industrial Cable Solutions

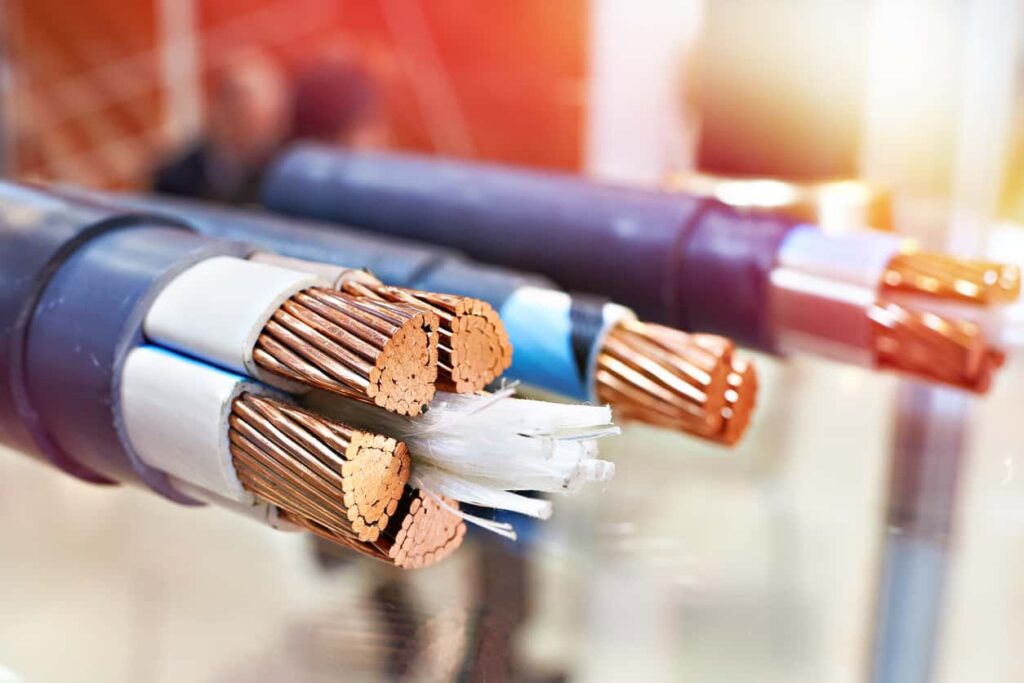

Industrial cables are designed to transmit power, data, or signals in demanding environments. Engineers design them to withstand mechanical stress, temperature fluctuations, and chemical exposure, unlike standard electrical cables.

Some common industries that rely on industrial cables include:

- Manufacturing & Automation – Powering robotics, conveyor systems, and machinery.

- Energy & Power Distribution – Delivering electricity from substations to industrial plants.

- Telecommunications & Data Transmission – Ensuring high-speed and interference-free signal transmission.

- Infrastructure & Transportation – Supporting railway systems, traffic signals, and underground utilities.

Key Factors to Consider When Choosing Industrial Cables

1. Application & Environment

The operating environment plays a huge role in determining which cable to use. Some key environmental factors to consider include:

- Indoor vs. Outdoor Use – Outdoor cables need UV-resistant and waterproof coatings.

- Extreme Temperatures – High-heat environments require heat-resistant insulation like XLPE or Teflon.

- Chemical and Moisture Exposure – If the cables will touch oil, chemicals, or water, make sure they have protective jacketing.

2. Voltage & Current Requirements

Selecting cables with the correct voltage and current capacity prevents overheating, power loss, and inefficiencies. Consider:

- Low-voltage cables for control systems, data transmission, and signal processing.

- Medium- and high-voltage cables for power distribution and heavy machinery.

3. Industrial Cable Solutions Materials & Insulation

- Copper vs. Aluminum Conductors – Copper offers better conductivity and flexibility, while aluminum is lightweight and cost-effective.

- Insulation Types – PVC (affordable, general use), XLPE (heat-resistant), and Teflon (chemical-resistant).

- Shielding Options – Shielded cables reduce electromagnetic interference (EMI), critical for sensitive data transmission.

4. Compliance & Industry Standards

Depending on your industry, you may need cables that meet specific safety and performance regulations:

- UL (Underwriters Laboratories) Certification – Ensures fire resistance and electrical safety.

- NEC (National Electrical Code) Compliance – Required for electrical installations in the U.S.

- IEEE & ISO Standards – Industry-specific requirements for power, telecom, and data systems.

5. Durability & Lifespan

Investing in high-quality cables reduces maintenance costs and system downtime. Key durability features to look for:

- Abrasion Resistance – Essential for cables exposed to mechanical wear.

- Flexibility & Bending Radius – Important for moving machinery and automation systems.

- Fire Retardant Properties – Crucial for cables in high-risk environments.

Common Types of Industrial Cable Solutions & Their Uses

There are various types of industrial cables designed for different applications:

Power Cables – Deliver electricity to industrial equipment.

Control Cables – Used in robotics and automation systems.

Instrumentation Cables – Carry low-voltage signals for monitoring and measurement.

Fiber Optic Cables – Provide high-speed data transmission with minimal interference.

Choosing the right type ensures smooth operation and efficiency.

Choosing a Reliable Industrial Cable Supplier

A high-quality industrial cable solution starts with a trusted supplier. When choosing a provider, consider:

- Certified & Tested Products – Ensure cables meet required safety standards.

- Customization Options – Some projects require custom cable configurations for unique applications.

- Technical Support – A knowledgeable supplier can help you select the best cable for your needs.

Industrial Cable Solutions that are Right for your Projects

Choosing the right industrial cable solutions requires careful consideration of environmental factors, voltage requirements, material durability, and industry standards. By knowing your project needs and choosing a good, compliant cable, you can ensure safety and long-lasting performance.

Need help selecting the right industrial cable for your project? Reach out to a trusted supplier to get expert guidance and high-performance solutions.