Keyword Focus: wire harness solutions

Goal: Showcase how precision-engineered wire harnesses enable reliable power transmission in space applications.

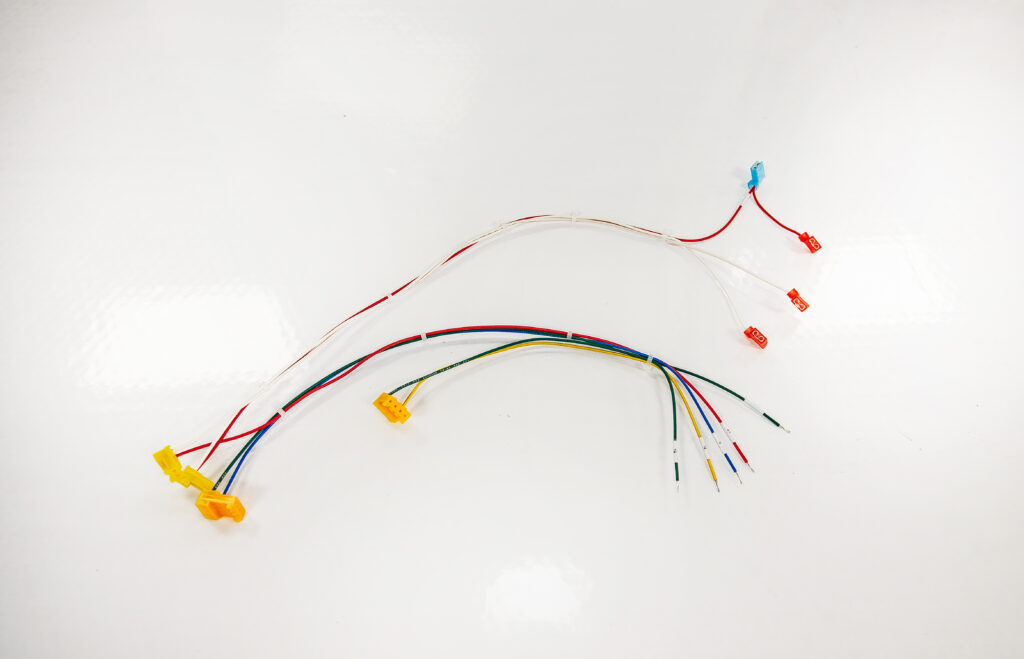

Custom Wire Harness Solutions for Spacecraft and Satellites

Reliability in space is crucial. Every spacecraft and satellite needs a steady power supply to function in tough conditions. If the wiring fails, even the best systems can malfunction. That’s why having secure electrical connections is essential for a successful mission.

Wire harness solutions must endure extreme temperatures, radiation, and intense vibrations during launch. They also need to work in the vacuum of space without breaking down. Well-built harnesses lower the risk of electrical failures that could threaten critical operations.

Precision-engineered wire harnesses focus on durability, reliability, and efficiency. Advanced engineering and thorough testing ensure each harness performs in the most demanding conditions.

Wire Harness Solutions in Spacecraft

Spacecraft operate in some of the harshest environments, where even minor electrical failures can have serious consequences. A well-manufactured wire harness provides stable power distribution, signal integrity, and long-term reliability.

Spacecraft wiring must withstand extreme conditions:

- The wires have to handle temperatures from -150°C to over 150°C. Plus, they need to be tough enough to take on heavy radiation without falling apart.

- The vibrations and shocks when launching is brutal, so the wiring must resist. And since space is a vacuum, those wires can’t let out any gases that might mess with essential components.

- Weight is critical, so the wiring must be both lightweight and strong.

- These missions can last years or even decades, so the wiring needs to keep performing without any maintenance.

- Every harness goes through a lot of testing to make sure it can handle the challenges of space. They go through thermal cycling, vibration tests, and checks for electrical integrity to mimic real-life conditions.

Precision Manufacturing for Reliable Wire Harness Solutions

Making wire harnesses for spacecraft demands strict adherence to industry standards. Manufacturing must follow rigorous quality controls. Each component needs to function well under any conditions. The process involves careful planning, material selection, and expert assembly.

Engineers select materials that can handle temperature changes, mechanical stress, and radiation. Each harness is custom-made to fit spacecraft specifications. It needs to be both lightweight and durable.

Insulation and shielding techniques prevent electromagnetic interference, which could disrupt sensitive electronics. Precision engineering, strict testing, and high-quality materials produce harnesses that meet space’s extreme demands. This way, every wire harness solution is up to the high standards of space travel.

Considerations for Space-Grade Wire Harnesses

Every component, from the wires to the connectors, is critical in maintaining electrical integrity. These harnesses must be capable of withstanding radiation exposure, and mechanical stress. The success of a mission often depends on the quality and resilience of these electrical systems.

When putting together components, there are a few key things to keep in mind:

- Choose materials that are both strong and lightweight, able to handle temperature changes, radiation, and physical stress.

- Connectors and terminals are crucial. If they fail, the entire mission can be at risk. Insulation and coatings help protect against radiation and prevent things from breaking down in a vacuum.

- Even small emissions from wires can mess with sensitive equipment, so using low-outgassing materials is a must.

- Precision is key during assembly. Technicians crimp, solder, and insulate connections with great care to avoid defects.

- Aerospace manufacturers need to be on top of their game when it comes to quality control, assuring that every wire harness meets high standards. Using backup systems, top-notch materials, and thoroughly testing each assembly, spacecraft can get reliable electrical solutions that can handle the tough conditions of space travel.

Conclusion

Wire harness solutions play a key role in spacecraft systems. They guarantee that power and communication stay steady. As missions get longer and trickier, the need for reliable electrical systems ramps up. Without a well-made wire harness, the spacecraft can run into functional issues.

Advancements in lightweight materials, enhanced shielding, and precision engineering continue to push the boundaries of space-grade wire harnesses. As the aerospace industry evolves, innovations in harness technology will support human spaceflight, deep-space exploration, and satellite advancements.